Sustainable Manufacturing: Eco-Friendly Practices in Brush Machine Factories

Sustainable Manufacturing: Eco-Friendly Practices in Brush Machine Factories

Blog Article

Sustainable manufacturing has become a vital part of the conversation in industries worldwide, and brush machine factories are no exception. As the demand for eco-friendly practices increases, manufacturers are finding innovative ways to reduce their environmental impact while maintaining high standards of production. One notable player in this field is Jiangmen Meixin Comb Brush Making Machine Manufacturing Co., Ltd., a company with over 37 years of experience in producing advanced 2-5 axis machines. Their dedication to sustainability not only reflects a commitment to the planet but also positions them as a leader in the brush manufacturing industry.

In recent years, the integration of sustainable practices in brush machine factories has led to significant advancements. From optimizing resource usage to reducing waste and emissions, manufacturers are increasingly focusing on eco-friendly processes. Jiangmen Meixin, with its extensive technical accumulation, showcases how experienced manufacturers can lead the way in adopting these practices. By prioritizing sustainability, they not only meet the demands of modern consumers but also contribute to a healthier and more sustainable manufacturing landscape.

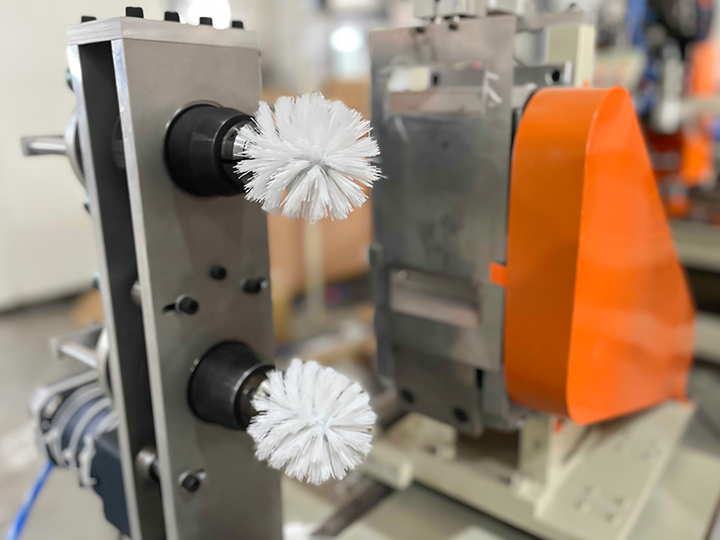

Meixin Brush Machine Setup

Overview of Jiangmen Meixin Comb Brush Making Machine Manufactoring Co., Ltd.

Jiangmen Meixin Comb Brush Making Machine Manufactoring Co., Ltd. is a renowned player in the brush machine industry, focusing on the design and production of advanced manufacturing machinery. With an impressive 37 years of experience, the company has built a solid foundation of expertise and technical knowledge. Their specialization in 2-5 axis machines facilitates the production of high-quality brushes, catering to a diverse range of applications.

The company's commitment to innovation is evident in its continuous development of new technologies and enhancements to existing machine designs. This dedication ensures that Jiangmen Meixin remains at the forefront of the industry, providing efficient and reliable solutions to manufacturers looking to optimize their brush production processes. Customers can rely on their expertise to meet both standard and custom manufacturing needs.

Sustainability is increasingly becoming a core focus for Jiangmen Meixin, as they aim to integrate eco-friendly practices throughout their operations. By investing in energy-efficient machinery and reducing waste, the company underscores its commitment to environmental responsibility. This approach not only benefits the planet but also positions Jiangmen Meixin as a forward-thinking leader in sustainable manufacturing practices within the brush machine sector.

Innovative Eco-Friendly Manufacturing Techniques

In the pursuit of sustainability, brush machine factories are increasingly adopting innovative eco-friendly manufacturing techniques. One of the significant advancements is the implementation of energy-efficient machinery. Jiangmen Meixin Comb Brush Making Machine Manufacturing Co., Ltd. has embraced this trend by developing 2-5 axis machines that consume less electricity while maintaining high productivity levels. This reduction in energy consumption not only lowers operational costs but also minimizes the environmental footprint of the manufacturing process.

Another effective technique is the use of biodegradable materials for brush production. Manufacturers are exploring natural bristle alternatives and recyclable components for their machines. This shift is not only beneficial for the environment but also meets the growing consumer demand for sustainable products. Jiangmen Meixin’s commitment to utilizing eco-friendly materials aligns with global trends and showcases the company's dedication to reducing plastic waste in the brush industry.

Water conservation is also a crucial aspect of eco-friendly manufacturing. Advanced water management systems are being integrated into production facilities to recycle and reuse water, significantly reducing waste. By investing in these technologies, companies like Jiangmen Meixin are setting an example for others in the industry. This not only fosters sustainable practices but also highlights the importance of responsible resource management in brush machine manufacturing.

Sustainable Materials Used in Production

The choice of materials is crucial in sustainable manufacturing, particularly in brush machine factories like Jiangmen Meixin Comb Brush Making Machine Manufacturing Co., Ltd. By utilizing eco-friendly raw materials, the company minimizes its environmental footprint while maintaining product quality. This includes the use of recycled plastics and bio-based composites, which not only reduce waste but also lessen dependence on petroleum-based materials.

Moreover, Jiangmen Meixin prioritizes sourcing materials from suppliers that adhere to sustainable practices. This commitment ensures that the entire supply chain aligns with eco-friendly values, further enhancing the sustainability profile of the products. For instance, using natural fibers for brush bristles helps reduce the reliance on synthetic materials, thereby promoting a cleaner environment.

In addition to raw materials, the company invests in innovative technologies that improve material efficiency. Advances in manufacturing processes allow for better utilization of materials, reducing waste during production. By adopting these sustainable materials and methods, Jiangmen Meixin not only adheres to environmentally responsible practices but also positions itself as a leader in the brush machine manufacturing industry.

Impact of Sustainable Practices on Efficiency

Implementing sustainable practices in brush machine factories like Jiangmen Meixin Comb Brush Making Machine Manufacturing Co., Ltd. has shown a significant positive impact on operational efficiency. By focusing on eco-friendly manufacturing processes, these companies can reduce waste and optimize resource use. This approach not only lowers production costs but also minimizes the environmental footprint, aligning business goals with ecological responsibility.

Moreover, the adoption of energy-efficient machinery and renewable energy sources has led to enhanced productivity. Factories employing 2-5 axis machines benefit from precision and reliability, which decreases downtime and increases output rates. This efficiency translates into a more streamlined production process, enabling manufacturers to meet demand while maintaining high-quality standards.

In addition, a culture of sustainability fosters innovation within the workforce. Employees become more engaged when they are part of a company that values eco-friendly practices, leading to increased motivation and collaboration. This commitment to sustainable manufacturing not only improves internal processes but also enhances the brand's reputation, attracting environmentally conscious consumers and clients.

Future Trends in Sustainable Manufacturing

As the demand for eco-friendly practices continues to rise, brush machine factories like Jiangmen Meixin Comb Brush Making Machine Manufacturing Co., Ltd. are increasingly focusing on sustainable manufacturing innovations. Emphasizing energy-efficient machinery and renewable energy sources, these factories are setting an example for the industry by reducing their carbon footprint. The integration of cutting-edge technology, such as automation and artificial intelligence, allows for optimized production processes that minimize waste and resource consumption.

Another significant trend is the adoption of circular economy principles, where manufacturers are rethinking product life cycles. This involves designing machines that utilize recyclable materials and implementing recovery programs for old equipment. Jiangmen Meixin is likely to lead in this area by enhancing the recyclability of their brush products and machinery components, ultimately reducing landfill contributions and promoting resource recovery within the industry.

Collaboration and transparency are becoming vital to sustainable practices. Companies are increasingly partnering with suppliers and stakeholders to create more sustainable supply chains. This trend encourages shared responsibility for environmental impacts and fosters innovation across the sector. Jiangmen Meixin’s commitment to sustainable practices reflects a growing recognition that collaboration is essential to achieving long-term sustainability goals within the brush machine manufacturing landscape.

Report this page